Home > Research > Research Highlights > Engineering > Using a Microwave Oven to Recover Platinum from Automotive Catalysts

date: 2018.03.12

Associate Professor ENDO Masatoshi, Ph.D. (Environment Chemistry/Analytical Chemistry)

Recycling of discarded vehicles is required in Japan. Recycling of ceramic-based automotive catalysts (devices for the purification of exhaust gas) is viewed as particularly difficult. Currently, platinum compounds are recovered by collecting crushed material for melting and refining. However, the crushing process results in the unwanted recovery of materials other than platinum compounds, and a large number of processes. This creates significant issues in terms of time and cost, and has created the needed for a simpler recovery technology for platinum compounds.

Our research has clarified that (1) platinum compounds can be melted in a short time by controlling the acid solution and oxygen concentration and irradiating with microwaves in a microwave oven, and (2) platinum compounds can be quickly removed in powder form by irradiating again with microwaves when reducing and recovering platinum compounds from that solution.

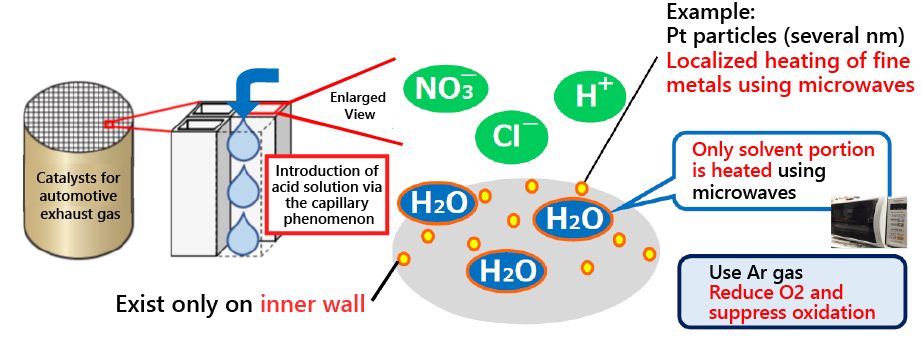

For process (1), we discovered that highly-efficient elution of palladium and platinum is possible for honeycomb-shaped ceramic catalysts that have been dismantled and remove. After injecting a small amount of heated aqua regia (acid with a 1:3 ratio of nitric acid to hydrochloric acid) by using the capillary phenomenon, we used a commercially-available microwave oven in an argon atmosphere to irradiate with microwaves (500W) for several dozen seconds and achieve elution. When using aqua regia, solubility is reduced when precious metal changes to metal oxide during melting. Consequently, we were able to suppress the oxidation of platinum compounds by using argon gas for the elution atmosphere. Furthermore, we succeeded in selective melting of catalyst fine particles which exist on the capillary surface, while also minimizing the melting of catalyst carriers.

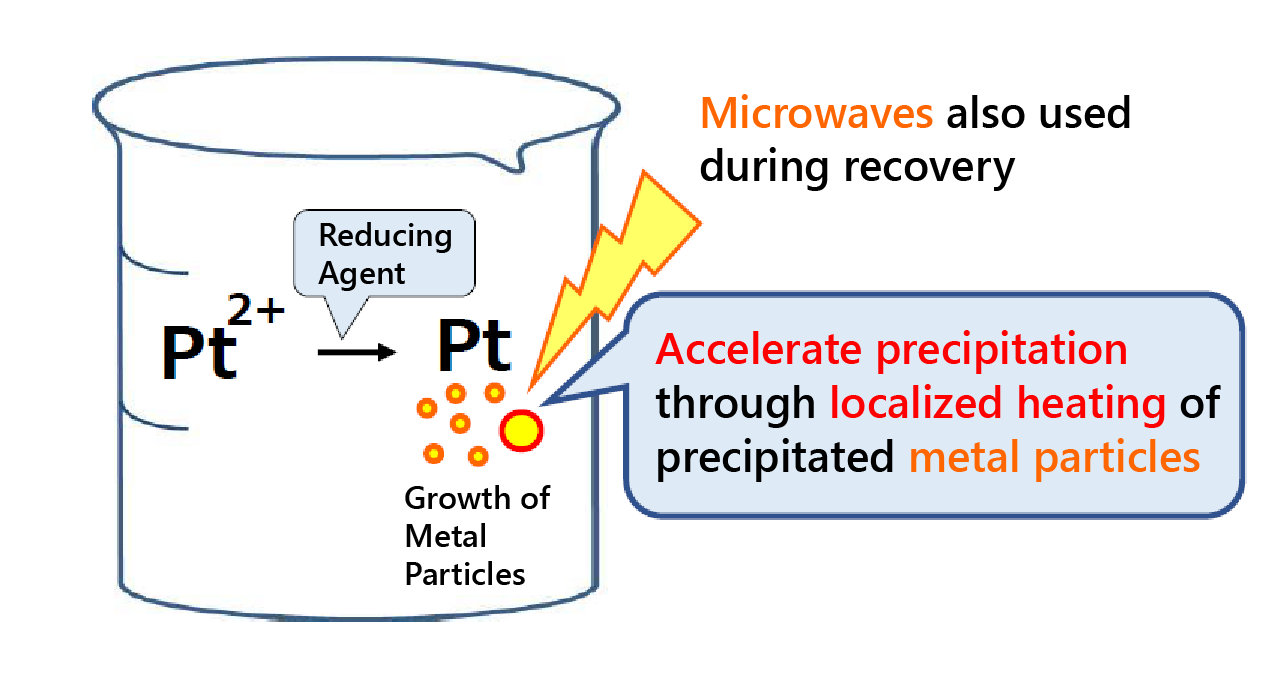

For process (2), we clarified that it is possible to quickly remove powder by irradiating for several dozen seconds with microwaves from a microwave oven at the time of recovery. Previously, this process required 24 hours using the conventional reducing agent.

These technologies make it possible to quickly and cheaply recover platinum compounds close to the dismantling site, without the need for special equipment and without incurring transportation. We expect this technology to be provided to the Japanese market.

Related Links