つなぐちから #11-English

Seiji Kakehata & Koya Eguchi

Crafting “experiences” and developing “people,” starting with manufacturing in Yamagata and then becoming the global standard through collaboration between medicine and engineering

2023.12.15

つなぐちから #11-English

Seiji Kakehata & Koya Eguchi

2023.12.15

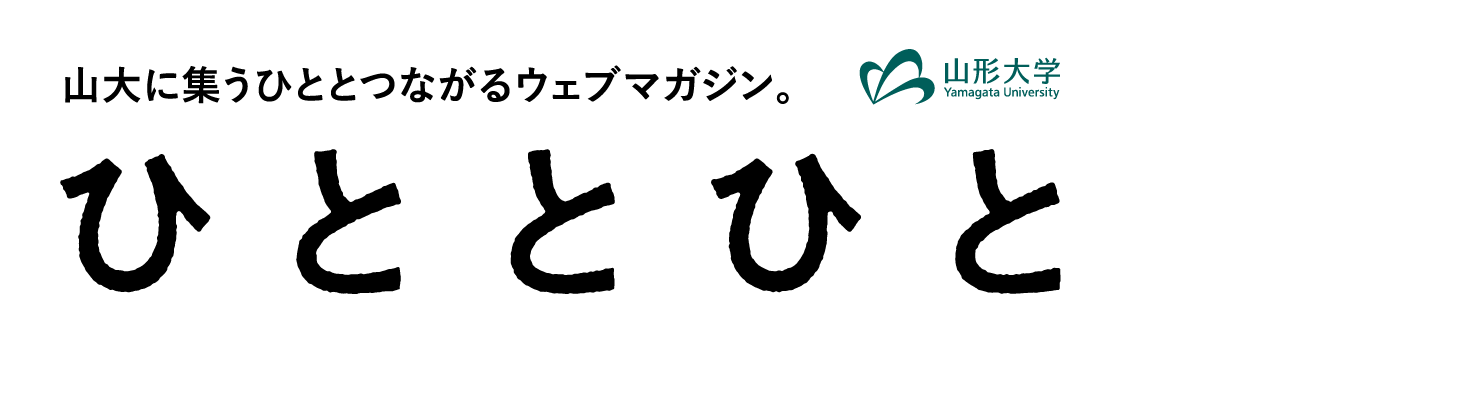

The ear is a sensory organ that is essential for communication, such as hearing and speaking. It is an important part of our body that greatly affects our quality of life, but for more than half a century surgery on the ear was typically performed by making a large incision behind the ear and removing the affected area under a microscope. What overturned conventional wisdom in the field was “transcanal endoscopic ear surgery (TEES).” This procedure was established for the first time ever by Professor Kakehata and his colleagues in the University’s Faculty of Medicine. TEES is a state-of-the-art medical procedure in which an endoscope is inserted through the ear canal, and the affected area is removed with an instrument while ensuring visibility with a monitor. Moreover, postoperative hospitalization is shortened from two weeks to a minimum of 3 nights and 4 days and there is little pain and no large scars, greatly reducing the burden on the patient. This is truly a paradigm shift in otologic surgery.

An indispensable component of this pioneering work in otology is the existence of medical instruments jointly developed by Professor Kakehata and local companies with advanced manufacturing technology in Yamagata. This article will focus on this “collaboration between medicine and manufacturing,” which is now in its 10th year.

--How is transcanal endoscopic ear surgery (TEES) related to manufacturing companies in Yamagata?

Kakehata: TEES, which is the procedure that we started, was so new that it revolutionized the field, and the development of new equipment was essential to facilitating that surgery. Since 2011, we have been working under the concept of “from original equipment to the standard.” Our goal is to make our original equipment the global standard. The wonderful thing is that we were able to achieve this with the technology of a manufacturing company in Yamagata.

We pioneered the “powered TEES” procedure, which uses an ultrasonic surgical instrument and a curved bur, and we jointly developed the “ZAOSONiC” ultrasonic surgical instrument to expand the use of this procedure. We also developed a “non-powered TEES” procedure. These procedures are garnering attention since they are ideal for the COVID-19 era, when aerosols (fine airborne particles) are less likely to be generated since surgery is performed by inserting a surgical instrument such as a curette (a surgical instrument used to remove bone and soft tissue) or an osteotome into the ear canal. These are unique procedures that originated in Yamagata.

ZAOSONiC, a motorized bone-cutting system using ultrasonic waves, was jointly developed with Micron Machinery Co., Ltd. in Yamagata City. Developing and marketing the system took about 8 years amidst competition from major foreign manufacturers. The ZAOSONiC can be operated without any extra effort, and it is used for lectures on simulated surgery on campus.

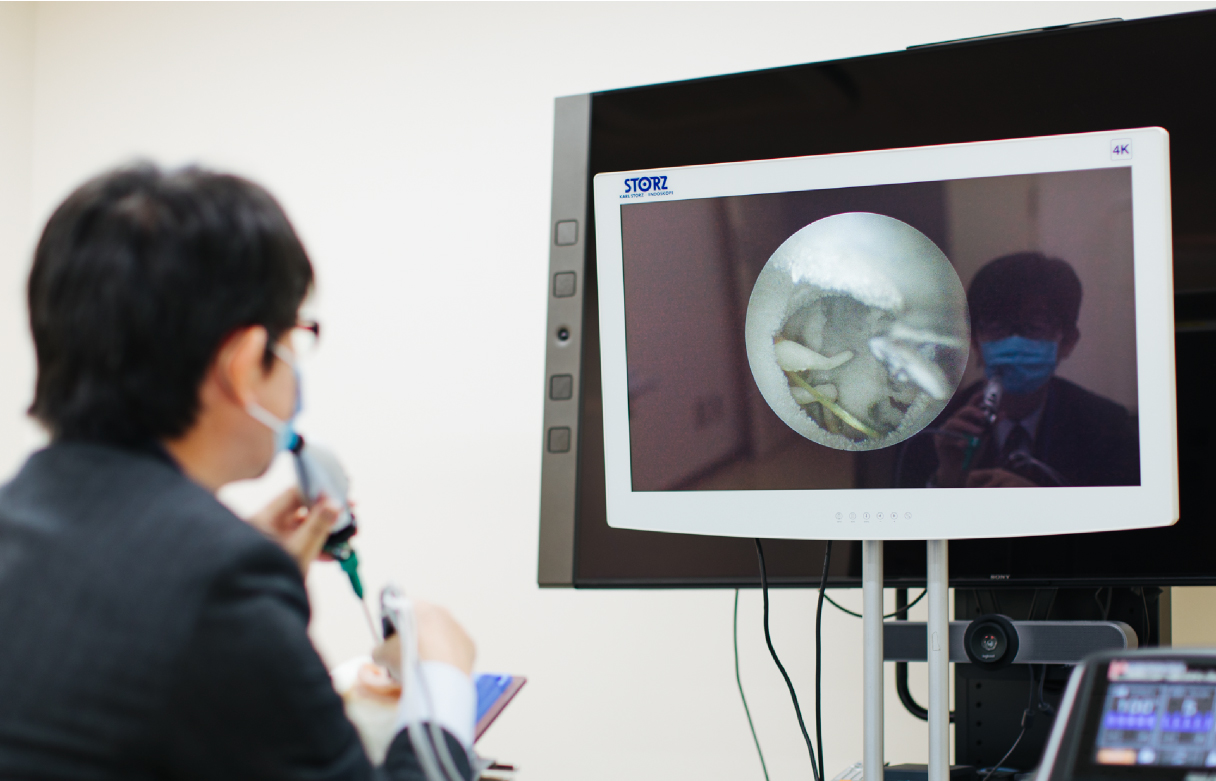

Kakehata: One of the instruments we have developed is the “non-slip” forceps thatwe made with a manufacturing company in the City of Kaminoyama. In conventional microsurgery, the surgeon holds a suction tube in his left hand and an instrument in his right hand and he looks through a microscope. In TEES, however, the surgical instrument is inserted into the narrow ear canal, which is 6 to 8 mm in diameter, and the procedure is performed while watching a monitor. This requires very delicate work, so use of non-slip forceps is vital.

“Non-slip” forceps jointly developed with Just Co., Ltd. in the City of Kaminoyama, Yamagata Prefecture

Diamonds are electrodeposited on the gripping surface.

Kakehata: There is something that Mr. Eguchi often says about manufacturing, which is that “every company in Yamagata has potential (valuable products and strengths).” However, those companies were unaware of how to develop that potential. In contrast, we physicians had many needs (what customers want from products). However, we were unaware of where to find the people who could fulfill those needs. Acting as a coordinator, Mr. Eguchi matched the potential with the needs they could fulfill. The fact that the ability to make this happen already existed in Yamagata Prefecture is amazing, but what is more important is the wonderful mechanism to make these connections.

--What was the context for the development of medical equipment through a collaboration between medicine and engineering?

Eguchi: Most manufacturing done by companies in Yamagata Prefecture involves contracted manufacturing for major companies. The development aspect is unnecessary, and competitiveness lies in production capacity and inexpensive labor. However, the number of orders received increased or decreased due to changes in market conditions, as exemplified by the bursting of the economic bubble and the collapse of Lehman Bros., as well as changes in the business circumstances of customers. Since then, companies have been run by relying on partners. So what could we do to enable companies to rely on themselves? Expectations were high for companies entering new sectors. This was especially true for the healthcare sector, which involves diversified business risk and less susceptibility to market conditions.

The Ministry of Economy, Trade and Industry (METI) started a project to encourage companies to enter medical field, and the Yamagata Prefecture Study Group on Next-generation Medical Equipment was established in the prefecture in May 2016. The Study Group is developing various initiatives to promote medical, welfare, and health-related industries.

Given this context, I have been working with Professor Kakehata since 2013, and this year marks the 10th year of our work together. He has advised me on the development of 5 medical instruments thus far, 3 of which are now commercially available and 2 of which are still being developed.

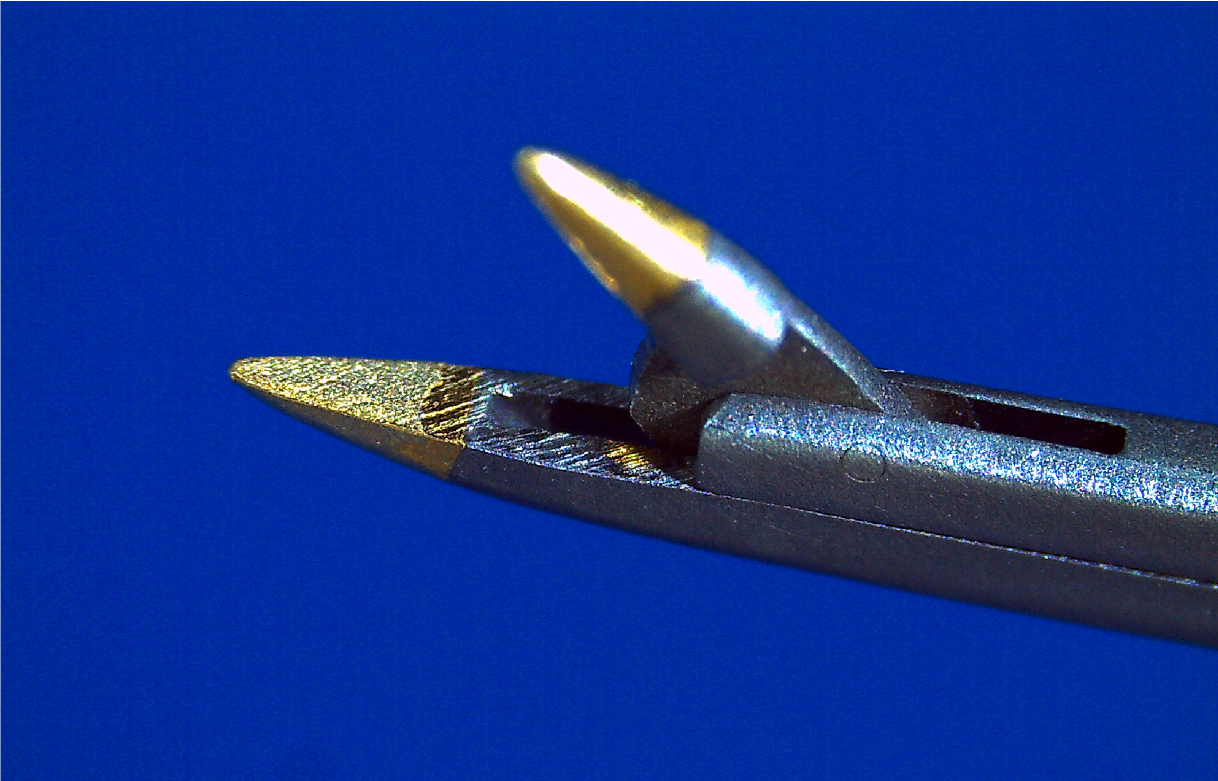

Kakehata: We created the TEES technology as open-access technology rather than as proprietary technology. Since 2012, our annual hands-on seminars have attracted many medical personnel from around the world. We want to spread our technology not just in Japan but all over the world. If the 10 people I have instructed each instruct 10 more people, then we can help more people around the world and bring joy to as many people as possible.

A poster for a hands-on seminar. Together with professors and students of Tohoku University of Art & Design, we created stylish and impactful signs and presentation videos.

In December 2022, the 4th World Congress on Endoscopic Ear Surgery was held in Kyoto and Yamagata. At the time, more than 650 otologists from 40 countries gathered to discuss “a new era of ear surgery.” The surgical instruments we developed in Yamagata were praised, and participants from all over the world flocked to purchase them. I am very happy that our efforts with Mr. Eguchi have now been recognized around the world in this manner.

Kakehata: We have made this new technology a reality with the help of new manufacturing capabilities in Yamagata. Next, we are proceeding to “craft experiences,” which is a step further. One is full-scale surgical training using a 3D printed model of the ear called the “Yamagata Model,” which was created together with Mr. Takagi of the medical technology staff and the Furukawa Laboratory of the Faculty of Engineering. We are now in the process of creating a model of the ear with an eardrum and a model of the nose as well.

A 3D model of the ear jointly developed by the Faculty of Medicine and the Faculty of Engineering at Yamagata University. The model is described as the “Yamagata Model” at academic conferences and seminars.

Kakehata: We want craft the “experience” of training surgeons in new procedures using the “Yamagata Model,” which combines new procedures from the Faculty of Medicine and proven technology from the Faculty of Engineering. By creating such a model, we would like to teach others about technology from Yamagata and train people using equipment from Yamagata, i.e., “things.” We would also like to utilize the strengths of Yamagata University to connect the development of “things” to the crafting of “experiences” and the development of “people.” That is what I think.

Eguchi: I think that I have been able to help meet some of the needs of “surgeons who want to develop new procedures but do not have the tools to perform them” through the use of manufacturing technology from Yamagata. We are now at the stage of “standardization,” which is the Professor’s goal. We are using the technology to train “specialists” and we are making the technology commercially viable. The goals of educational institutions, which foster people, and manufacturing companies differ, but there is a huge advantage to collaboration between the two. This is one of the interesting aspects of collaboration between industry and academia.

In manufacturing, what is important is not to focus on the product but on what people want to do with the product. Selling a product for 100 yen or having people buy it for 1,000 yen is boring. As the Professor says, the most interesting aspect is to develop more “people” and to “create a market (an experience)” using the product. The Professor has been an influencer in spreading this concept.

--Lastly, what is your vision for the future?

Eguchi: The development and marketing of medical equipment has made progress, but the original goal of my efforts is “for manufacturing companies to act and operate independently.” That goal has yet to be achieved over the past 10 years. I will continue my work each day in order to achieve that goal.

Kakehata: This surgery, which is one of the world’s most advanced procedures, is performed at Yamagata University. The University is the venue and it has the tools to teach this procedure. However, this cannot be achieved by me alone or a single medical office or a single university. We are doing this with the help of people from around Japan and people from around the world. Our ultimate desire is to bring joy to as many people around the world as possible. But we have not reached the summit; we are still partway down the path. To achieve that goal, we must continue on our current path, one step at a time. I want to continue making steady progress, one step at a time, toward the goal of surgery that completely cures the patient while placing almost no burden on him or her.

つづきを読む

Kakehata Seiji●MD, PhD, and Professor, Yamagata University Faculty of Medicine. Chairman of the Japan Otological Society. His specialty is otorhinolaryngology. He has pioneered the development of TEES, an endoscopic ear surgery that places little physical and mental burden on the patient. In December 2022, he chaired the 4th World Congress on Endoscopic Ear Surgery in Kyoto and Yamagata. More than 650 otologists from 40 countries gathered to discuss the “New Era of Ear Surgery.”

Koya Eguchi●Coordinator of Collaboration among Industry, Academia, and Government, Yamagata Organization to Promote Industrial Technology. Born in Yamagata Prefecture. After working for a semiconductor manufacturer, he assumed his current position in 2007 and completed his graduate studies at Yamagata University’s Graduate School of Science and Engineering while in that position. He is currently working hard to promote innovative management efforts by companies in Yamagata Prefecture.

*Details and affiliations are current as of March 2023.